ZAHORANSKY EDGE: High-Tech, Design Freedom and Sustainability in Toothbrush Manufacturing

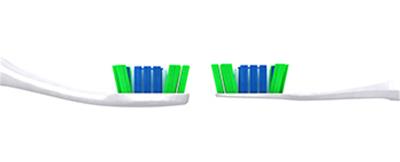

In the oral care industry, the high demands on dental health, creative brush design, and economical, sustainable production processes are increasingly converging. With EDGE, ZAHORANSKY has launched a compact production system that enables the efficient manufacture of anchor-free monomaterial toothbrushes – while meeting all requirements in terms of design, sustainability, and cost-effectiveness. The innovative anchor-free production process thermally bonds filament bundles directly to the brush head, allowing handles, heads, and filaments to be made from the same type of plastic. This not only allows for head designs that are up to 70 percent thinner but also ensures a constant output of up to 30 brushes per minute – regardless of head geometry or number of filament bundles.

In the oral care industry, the high demands on dental health, creative brush design, and economical, sustainable production processes are increasingly converging. With EDGE, ZAHORANSKY has launched a compact production system that enables the efficient manufacture of anchor-free monomaterial toothbrushes – while meeting all requirements in terms of design, sustainability, and cost-effectiveness. The innovative anchor-free production process thermally bonds filament bundles directly to the brush head, allowing handles, heads, and filaments to be made from the same type of plastic. This not only allows for head designs that are up to 70 percent thinner but also ensures a constant output of up to 30 brushes per minute – regardless of head geometry or number of filament bundles.The toothbrushes, which are made entirely from a single material and without anchor wire, are 100 percent recyclable and therefore particularly resource efficient. "The innovation carousel in the highly competitive oral care market is spinning faster than ever. At the same time, manufacturers are under increasing cost pressure when introducing new products. In addition, recyclability and sustainability are becoming increasingly important to end consumers. We are delighted with the first joint projects and the positive customer feedback on EDGE. This confirms our solution expertise for hygienic, stylish, and environmentally friendly products," says Kevin Eisemann, Head of Development at ZAHORANSKY.

The benefits for end users begin at the very end of the manufacturing chain: thanks to extremely delicate geometries, the EDGE achieves head thicknesses of only about 1.5 millimeters. The edge distances between the filament and the brush contour shrink to just 0.8 millimeters. This is ideal for better reaching the rear areas such as wisdom teeth and molars during daily dental care. In addition, the filament bundles are not pressed together with anchors, but thermally bonded. This prevents the formation of cavities in which saliva, water, or germs could collect, reducing the risk of contamination of the oral cavity, gums, and teeth by germs or mold.

The benefits for end users begin at the very end of the manufacturing chain: thanks to extremely delicate geometries, the EDGE achieves head thicknesses of only about 1.5 millimeters. The edge distances between the filament and the brush contour shrink to just 0.8 millimeters. This is ideal for better reaching the rear areas such as wisdom teeth and molars during daily dental care. In addition, the filament bundles are not pressed together with anchors, but thermally bonded. This prevents the formation of cavities in which saliva, water, or germs could collect, reducing the risk of contamination of the oral cavity, gums, and teeth by germs or mold.New Design Freedom for Form and Function

From a design perspective, EDGE sets new standards: “Since pre-drilled holes are no longer required in the head, EDGE offers manufacturers great design freedom,” explains Eisemann. Bundles for interdental focus, large-area tufts for massage, and even complex mixed forms can be set in a single production step and then fused with a counter profile at the desired height. Another advantage for manufacturers: this variety of options can be produced more easily and cost-effectively on the EDGE, as magnetically fixed pattern parts are used instead of expensive mold bars for injection molding tools. Most design changes can therefore be made quickly, without tools, and without risk of mix-ups.

Faster Time to Market

To implement new designs quickly, precisely, and cost-effectively, ZAHORANSKY also supports manufacturers with its own rapid prototyping service. New product designs are reviewed at an early stage in collaboration with the customer. Findings, such as how new hole field geometries or profile heights affect haptics, cleaning performance, and brand image, are thus directly incorporated into the further development process and accelerate time to market.

Output That Pays Off

The EDGE also sets standards in terms of business efficiency. “Since the process feeds in all bundles simultaneously, the cycle time of up to 30 toothbrushes per minute remains constant, regardless of the complexity of the brush head,” explains Eisemann. At the same time, there are no costs for anchors or the purchase of multiple injection molding inserts. Thanks to its compact design, requiring only 11 square meters of space, the EDGE can be integrated into existing production environments. Installation and commissioning by the ZAHORANSKY service team on site can often be completed within one working day thanks to the machine's extensive preconfiguration. During operation, the intuitive ZMI 4.0 control unit guides the operating personnel safely through all production and maintenance processes. In addition, the automatic feed mechanism for brush bodies and filaments means that only occasional human intervention is required for refilling. In times of skilled labor shortages, the EDGE not only provides a stable basis for calculable unit costs but also makes the entry into anchorless monomaterial technology economically attractive and feasible for medium-sized manufacturers.

The EDGE also sets standards in terms of business efficiency. “Since the process feeds in all bundles simultaneously, the cycle time of up to 30 toothbrushes per minute remains constant, regardless of the complexity of the brush head,” explains Eisemann. At the same time, there are no costs for anchors or the purchase of multiple injection molding inserts. Thanks to its compact design, requiring only 11 square meters of space, the EDGE can be integrated into existing production environments. Installation and commissioning by the ZAHORANSKY service team on site can often be completed within one working day thanks to the machine's extensive preconfiguration. During operation, the intuitive ZMI 4.0 control unit guides the operating personnel safely through all production and maintenance processes. In addition, the automatic feed mechanism for brush bodies and filaments means that only occasional human intervention is required for refilling. In times of skilled labor shortages, the EDGE not only provides a stable basis for calculable unit costs but also makes the entry into anchorless monomaterial technology economically attractive and feasible for medium-sized manufacturers.Standard-Compliant Manufacturing

The EDGE meets all international testing criteria for manual toothbrushes. Internal measurement series conducted by ZAHORANSKY also prove that the thermally bonded tufts of the EDGE can withstand much higher pull-out forces. It also passes the pendulum impact test for breakage resistance of ultra-thin heads, which is mandatory in Europe and the USA, despite a head thickness of only 1.5 millimeters, which is far below the industry standard of 4 to 5 millimeters. This exceptional stability forms the basis for worldwide approvals – from FDA registration in the USA to CE marking in the European Economic Area. “The EDGE therefore not only offers hygienic and economic advantages but also provides our customers with the regulatory security to be able to sell their products in all relevant target markets,” says Eisemann.

The EDGE meets all international testing criteria for manual toothbrushes. Internal measurement series conducted by ZAHORANSKY also prove that the thermally bonded tufts of the EDGE can withstand much higher pull-out forces. It also passes the pendulum impact test for breakage resistance of ultra-thin heads, which is mandatory in Europe and the USA, despite a head thickness of only 1.5 millimeters, which is far below the industry standard of 4 to 5 millimeters. This exceptional stability forms the basis for worldwide approvals – from FDA registration in the USA to CE marking in the European Economic Area. “The EDGE therefore not only offers hygienic and economic advantages but also provides our customers with the regulatory security to be able to sell their products in all relevant target markets,” says Eisemann.For more information, visit the ZAHORANSKY website or use the contact information via the link below:

Related Companies

Zahoransky AG

Germany

Zahoransky Moulds & Machines Pvt Ltd

India

Zahoransky Ltd

Japan

ZAHORANSKY SA Unipersonal

Spain

Zahoransky USA Inc.

United States

ZAHORANSKY do Brasil Comércio de Máquinas Ltda.

Brazil

Related Articles

CEO Ulrich Zahoransky Retires After Four Decades

18/11/2025

Company News -

ZAHORANSKY at K 2025: Innovations for Plastics and Medical Technology in Focus

17/09/2025

Company News -

ZAHORANSKY Will Exhibit at CIBRUSH 2025 and Deeply Cultivate the Asian Brush Market!

19/08/2025

CIBRUSH News -

ZAHORANSKY Z.ORCA 18: High Performance in a Small Space

12/08/2025

Product News -

ZAHORANSKY Machine Portfolio Easy to Retrofit for the Production of Toothbrushes with Plastic Anchor

14/05/2025

Product News -

Change of Executive Board at ZAHORANSKY AG

11/10/2024

Company News -

Heinz Zahoransky Passes Away at the Age of 95

30/08/2024

Company News -

ZAHORANSKY EDGE Enables Efficient Production of Metal-Free Mono-Material Toothbrushes

18/05/2024

Product News -

ZAHORANSKY Sells Mold and Tool Shop in Rothenkirchen

30/01/2024

Company News -

Z.PARD MT for Fully Automated Brush Production

13/11/2023

Product News -

Z.PUMA by ZAHORANSKY: Maximum Performance and Flexibility

06/10/2023

Product News -

The New Z.SCORP from ZAHORANSKY

12/07/2023

Product News -

A Mono-Material Toothbrush by ZAHORANSKY and Evonik

06/03/2023

Archived -

New ZAHORANSKY Microsite Provides an Overview of the Latest Medical Technology Solutions

26/01/2023

Archived -

ZAHORANSKY and KOCH Pac-Systeme Establish Close Cooperation in the Blister Packaging Sector

02/11/2022

Archived -

ZAHORANSKY Introduces Expanded Management Team in India

26/07/2022

Archived -

ZAHORANSKY Repositions Sales and Marketing

02/02/2022

Archived -

ZAHORANSKY Bids Farewell to Interbrush - New Formats for Personal Exchange

07/12/2021

Archived -

ZAHORANSKY Introduces New Apps for Contactless Support and Direct Spare Parts Orders

16/03/2021

Archived -

ZAHORANSKY Group Acquires Dialysis Division of FLG Medizintechnik GmbH

18/01/2021

Archived -

ZPARE – New Application by ZAHORANSKY

17/11/2020

Archived -

ZAHORANSKY Z.PARD: Reworked Design for Optimized Operating and Production Processes

02/11/2020

Archived -

New Micro-Injection Mold Produces Toothbrush Tips for the Z.VAMP from ZAHORANSKY AG

11/09/2020

Archived -

ZOLVE – New Application by ZAHORANSKY

27/08/2020

Archived -

Dr. Bernd Stein to Become New Chief Technical Officer at ZAHORANSKY AG

31/07/2020

Archived -

Z.RAY: For the Precise and Hygienic Manufacture of Wooden Toothbrushes

10/07/2020

Archived -

ZAHORANSKY Receives Large Order for Systems for the Processing of Vaccine Containers

10/07/2020

Archived -

New ZAHORANSKY Customer Magazine

26/06/2020

Archived -

ZAHORANSKY Improves Output and Operating Comfort in Twisted-in-Wire Brushes with New Lines and Improved Machine Controls

25/06/2020

Archived -

ZAHORANSKY - New Machines, Systems and Technologies

15/06/2020

Archived -

ZAHORANSKY Newsboard – Update

21/04/2020

Archived -

Record Figures for ZAHORANSKY: 2019 is the Best Year in the Company History

15/04/2020

Archived -

ZAHORANSKY Launches Newsboard with Comprehensive Information Regarding Current Developments During Coronavirus Crisis

01/04/2020

Archived -

Zahoransky USA Deemed Essential Business

27/03/2020

Archived -

ZAHORANSKY Brush and Broom Machines for Hygienic Measures

03/03/2020

Archived -

Z.SHARK Family of High-Performance Tufting Machines Now Optionally Available with Double Turret

10/02/2020

Archived -

ZAHORANSKY: Future-Proofing “Black Forest Quality” Made in India

13/12/2019

Archived -

Z.PACK 6 | 8 | 11 from ZAHORANSKY: The Competition Can Pack it All Up

12/10/2019

Archived -

Environmental Management at ZAHORANSKY

11/10/2019

Archived -

ZAHORANSKY at K 2019: The Z factor is Included

23/09/2019

Archived -

ZAHORANSKY Has Received Several Awards

01/08/2019

Archived -

Winfried Ebner to become third Board Member at ZAHORANSKY AG

26/03/2019

Archived -

Happy Birthday Dr. Heinz Zahoransky!

10/09/2018

Archived -

ZAHORANSKY USA Open House 2018

12/07/2018

Archived -

ZAHORANSKY receives the "Innovation Award 2018"

29/06/2018

Archived -

Beef Up Your New Z.LION from ZAHORANSKY - The King of the Brush & Broom Production Jungle

23/05/2018

Archived -

Visit ZAHORANSKY at Plastpol 2018 - The 21st International Fair of Plastics and Rubber

09/05/2018

Archived -

Visit ZAHORANSKY at the NPE Show

06/04/2018

Archived -

ZAHORANSKY: Introducing Our Beastly New Website.

13/03/2018

Archived -

Power for Your Brush Production: Z.LION from ZAHORANSKY

28/02/2018

Archived -

High-Tech Solutions for your Personal Care Products from ZAHORANSKY

17/02/2018

Archived -

ZAHORANSKY Rises for the Fourth Time in a Row

06/02/2018

Archived -

ZAHORANSKY – Where the Future is at Home

13/10/2017

Product News -

ZAHORANSKY Achieves Highest Order Intake in Company's History

05/09/2017

Archived -

ZAHORANSKY USA Inc. Change in Management and Service Technician

03/08/2017

Archived -

Next Generation of Brush Production: Zahoransky's Z.LION

19/07/2017

Archived -

ZAHORANSKY: Ideas Make the Difference

19/07/2017

Archived -

Visit Zahoransky At Chinaplas 2017!

04/05/2017

Archived -

ZAHORANSKY given the 2016 MSG Award

18/04/2017

Archived -

Zahoransky Looks Forward to Celebrating 100 Years at the ABMA Convention

15/03/2017

Archived -

ZAHORANSKY Automation & Molds and Packaging

17/02/2017

Archived -

ZAHORANSKY joins Forces of Sales & Service in Shanghai

03/02/2017

Archived -

ZAHORANSKY Continues Upswing Thanks to Strong Demand

03/02/2017

Archived -

Inauguration of ZAHORANSKY’S New Plant in Spain

25/10/2016

Archived -

Z.PARD from ZAHORANSKY

01/09/2016

Archived -

Zahoransky Brings a Black Forest Feeling to Interbrush

26/05/2016

Archived -

Welcome to ZAHORANSKY – Where the Future is at Home

22/04/2016

Archived -

Zahoransky do Brazil

21/04/2016

Archived -

Production of High Quality Toothbrushes on a Milacron Injection Molding Machine

20/04/2016

Archived -

ZAHORANSKY Set to Attend the ABMA Convention 2016

26/02/2016

Archived -

Continuous and solid growth of ZAHORANSKY GROUP

28/01/2016

Archived -

ZAHORANSKY Receives (Re)certification

30/10/2015

Archived -

ZAHORANSKY Booth Party

20/10/2015

Archived -